Shrink your cycle time on complex castings without scrap

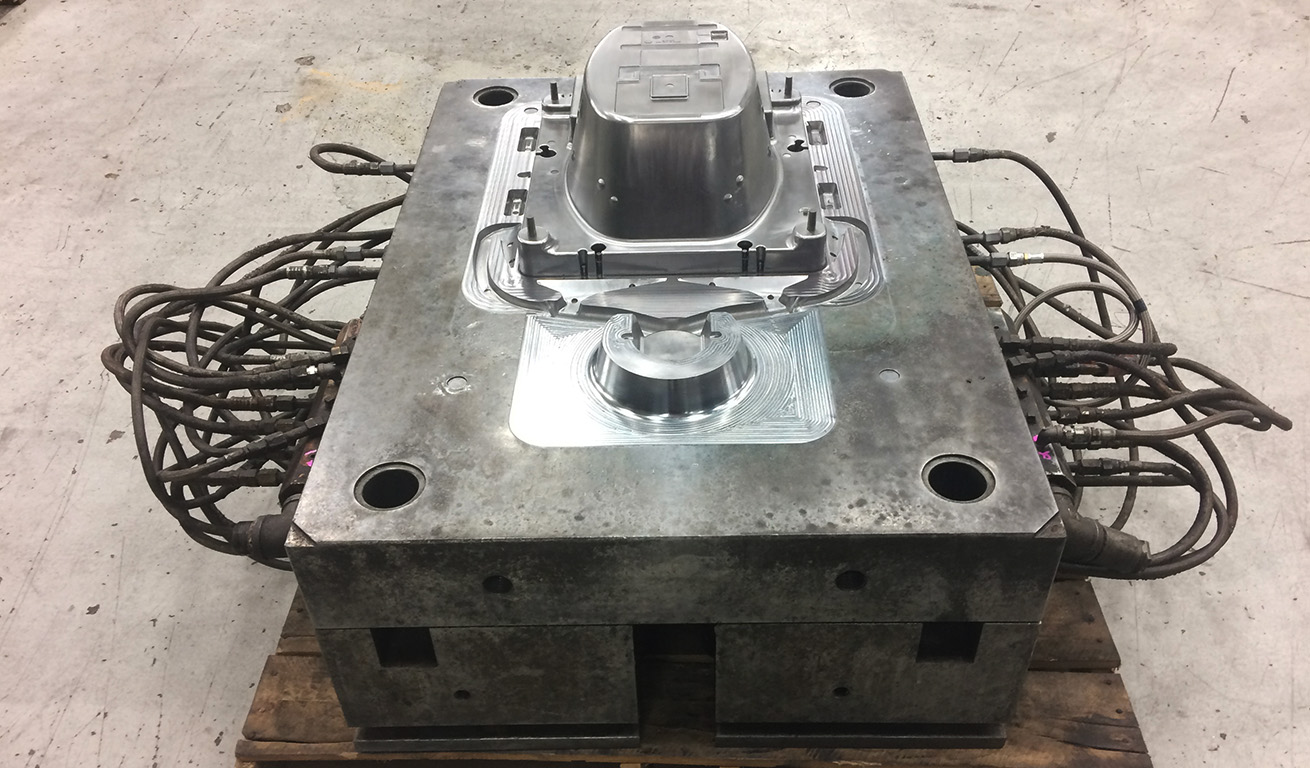

Die cast tooling produces castings that lower cost with fast cycle times under high pressure. Decades of experience in the high-volume automotive industry means we’ve designed die cast tooling for many different applications.

You need die cast tooling when you need speed and repeatability. And our die cast tooling utilizes slides, water cooling systems, rudders, and more to shrink cycle times and deliver more consistent casts.

Smart engineering minimizes your margin for error

Dimensional accuracy eliminates flashes

It takes very little space for pressurized metal to leak and cause your casting to flash. Dealing with flash drives labor and material costs up, but well-designed tight tolerances reduce scrap and rework, especially for intricate parts.

We design and bench our tooling for the highest physically achievable accuracy, tight tolerances, and a smooth surface finish to your part. Because the more process control you achieve, the more cost-effective your tooling will be.

Die cast tooling technical specifications

Die cast tooling solutions from Anderson are for advanced manufacturing processes producing complex, high-performance products.

- Our tooling is typically made with premium H13 steel to prevent cracking

- Castings can be made of aluminum, magnesium, or zinc

- We can design for hot chamber machines and cold chamber machines

The total solution for your foundry mold needs

Whether your needs are complex, simple, or somewhere in between, our expertise ensures you get durable, reliable equipment that creates accurate and consistent parts from the first shot.

-

A one-stop shop for your whole project

Design, simulation, casting process, machining, benching, validation — we’ll meet you anywhere in your process. No matter the challenge, we can solve it in our Michigan facility.

-

Decades of experience

Our team of design engineers and journeyman patternmakers have delivered hundreds of molds and core boxes across every industry. And their expertise is on call when you need it.

-

Modern, data-driven designs

All of our molds and core boxes start in the digital world. Problem-solving in simulations keeps issues out of your foundry and generates accurate data that makes machining, maintenance, and repairs easy.