Prototype faster with an experienced partner

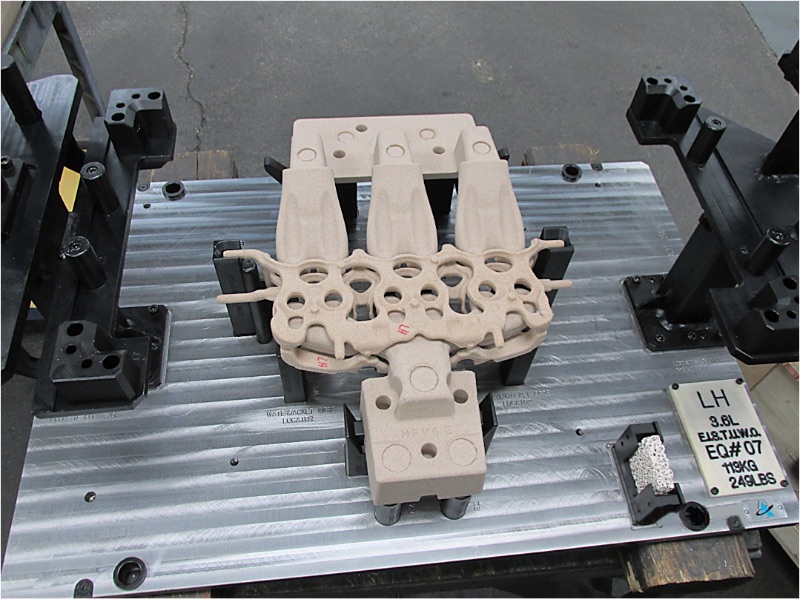

If you need to prototype a new component and don’t have capacity or lack internal expertise, you may struggle getting the time of day from your high-volume machine shop. Our team can help you design the fixturing for your casting and machine your part in small batches until you’re ready to scale.

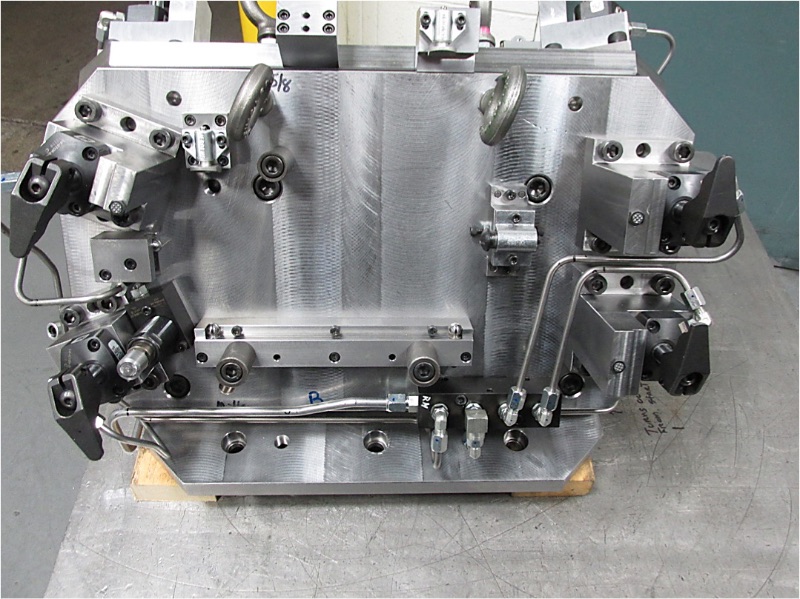

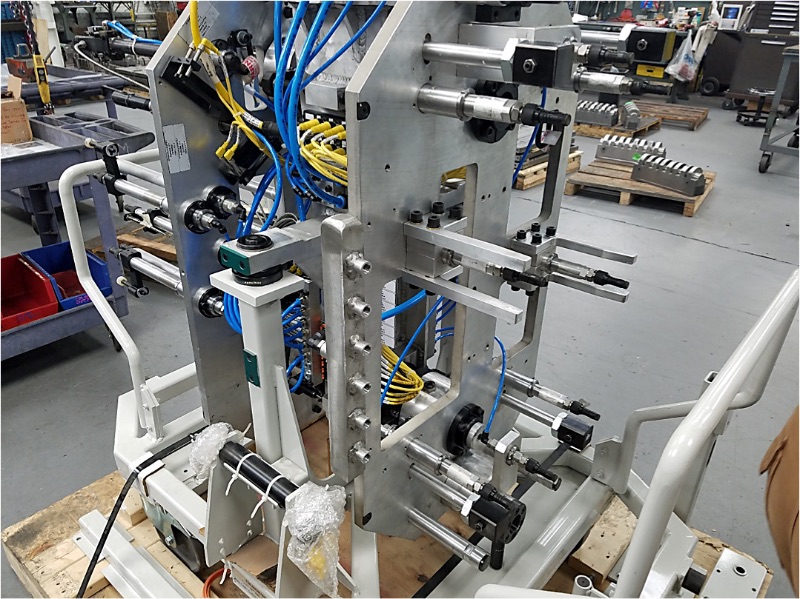

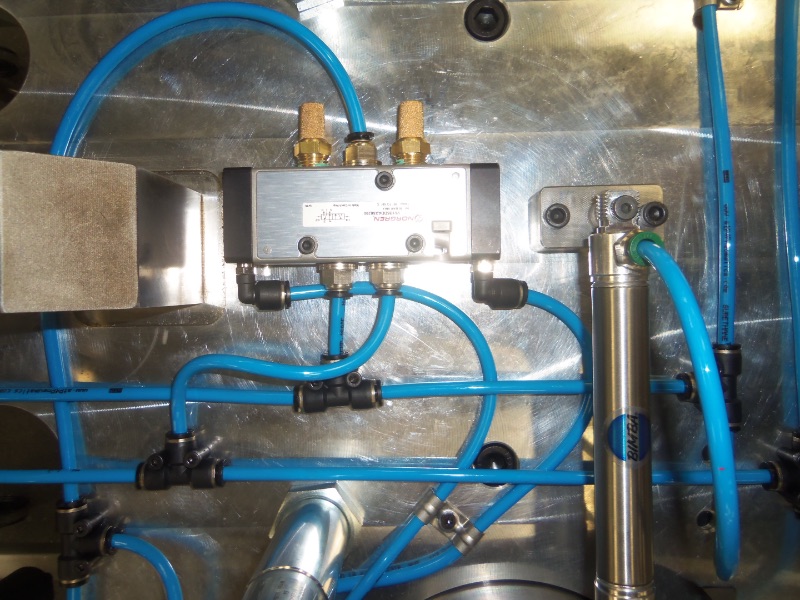

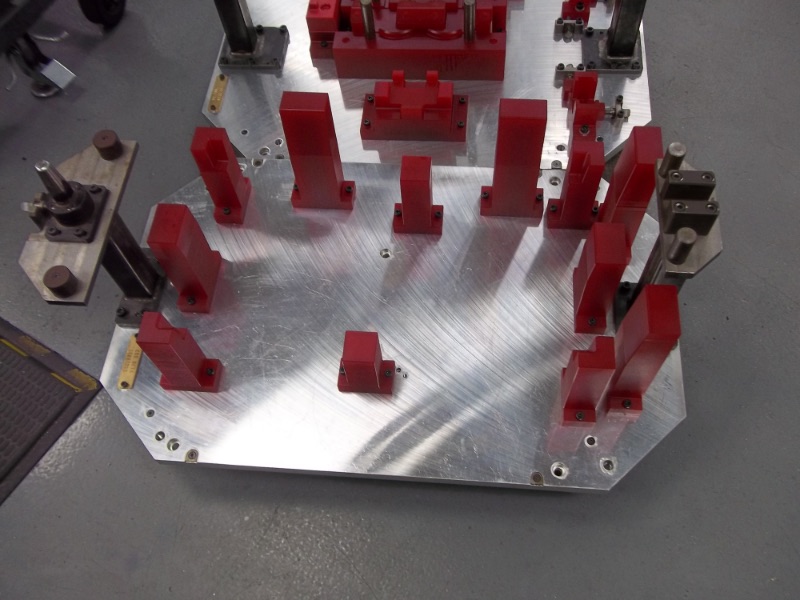

Whether you need just one or two parts machined, or two dozen, we can handle your project on one of our three 5-axis machines, two Hermle machines, or our Grobe machine. We’ll design and build the fixture in-house, as well, to make sure we produce perfect parts every time.

Fixturing and machining handled in a single shop

Easily locate machined features again and again

Moving a new component to volume production with speed and efficiency requires a trustworthy prototyping process. When you’re only machining a handful of parts, it’s critical each is correct, so every revision gets you closer to volume production.

Whether you need a collar machined down, a center hub machined out, or something more complex, we’ll work with you to build a fixture that holds your part correctly for a perfect finish every time. Just send us a CAD file, and we’ll start collaborating.

Fixturing and small-batch machining technical specifications

Anderson Global maintains capacity in our shop specifically to work with foundries on small-batch machining projects.

- We can machine aluminum, ductile iron, gray iron, or any other type of foundry castings

- While we can work with simple fixturing castings and projects, we are experts at complex parts on 5-axis machines

The total solution for your foundry mold needs

Whether your needs are complex, simple, or somewhere in between, our expertise ensures you get durable, reliable equipment that creates accurate and consistent parts from the first pour.

-

A one-stop shop for your whole project

Design, simulation, casting process, machining, benching, validation — we’ll meet you anywhere in your process. No matter the challenge, we can solve it in our Michigan facility.

-

Decades of experience

Our team of design engineers and journeyman patternmakers have delivered hundreds of molds and core boxes across every industry. And their expertise is on call when you need it.

-

Modern, data-driven designs

All of our molds and core boxes start in the digital world. Problem-solving in simulations keeps issues out of your foundry and generates accurate data that makes machining, maintenance, and repairs easy.