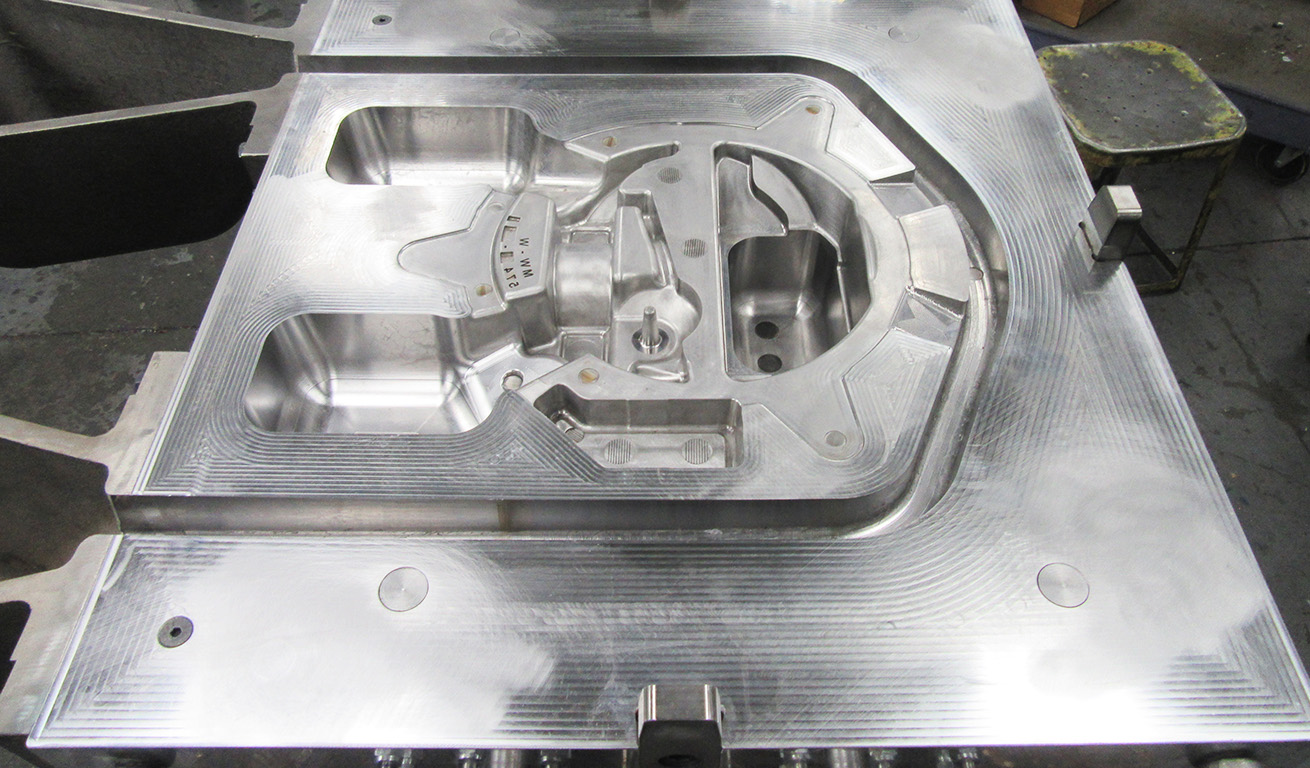

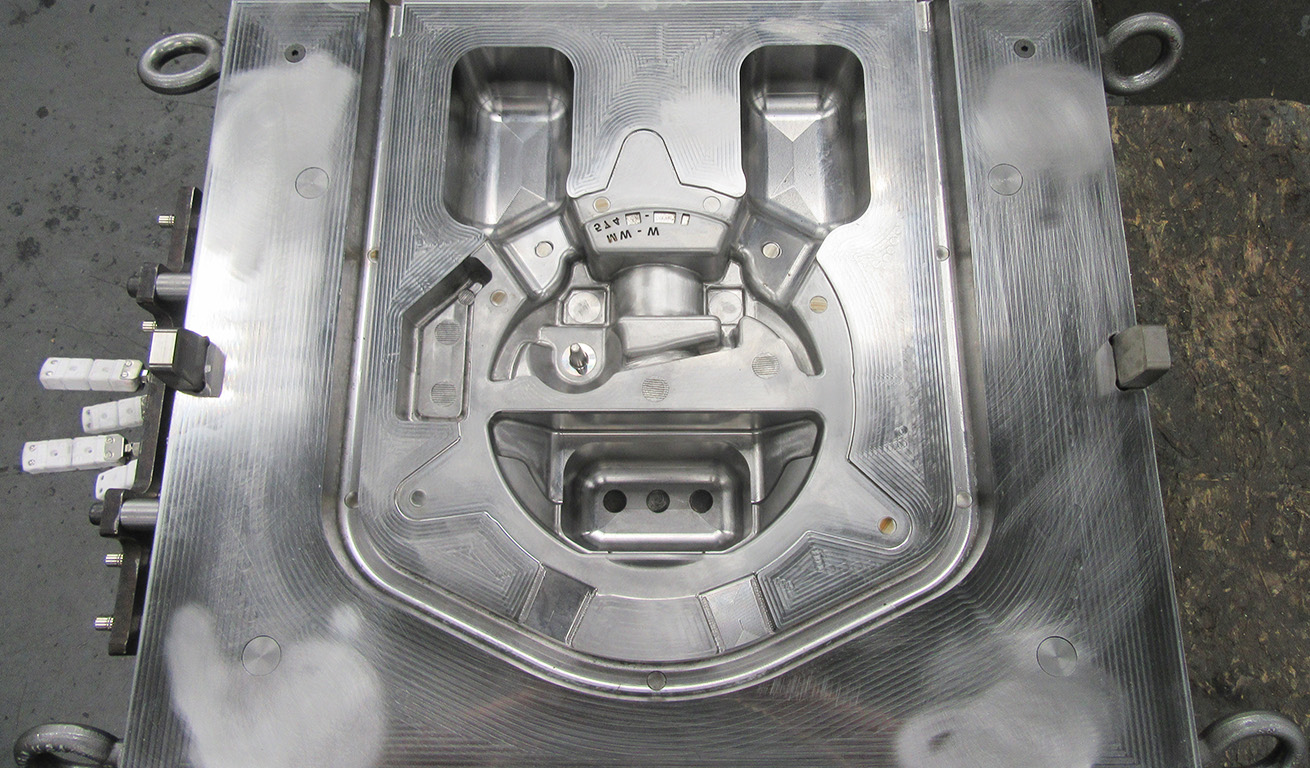

From cavities to core packages

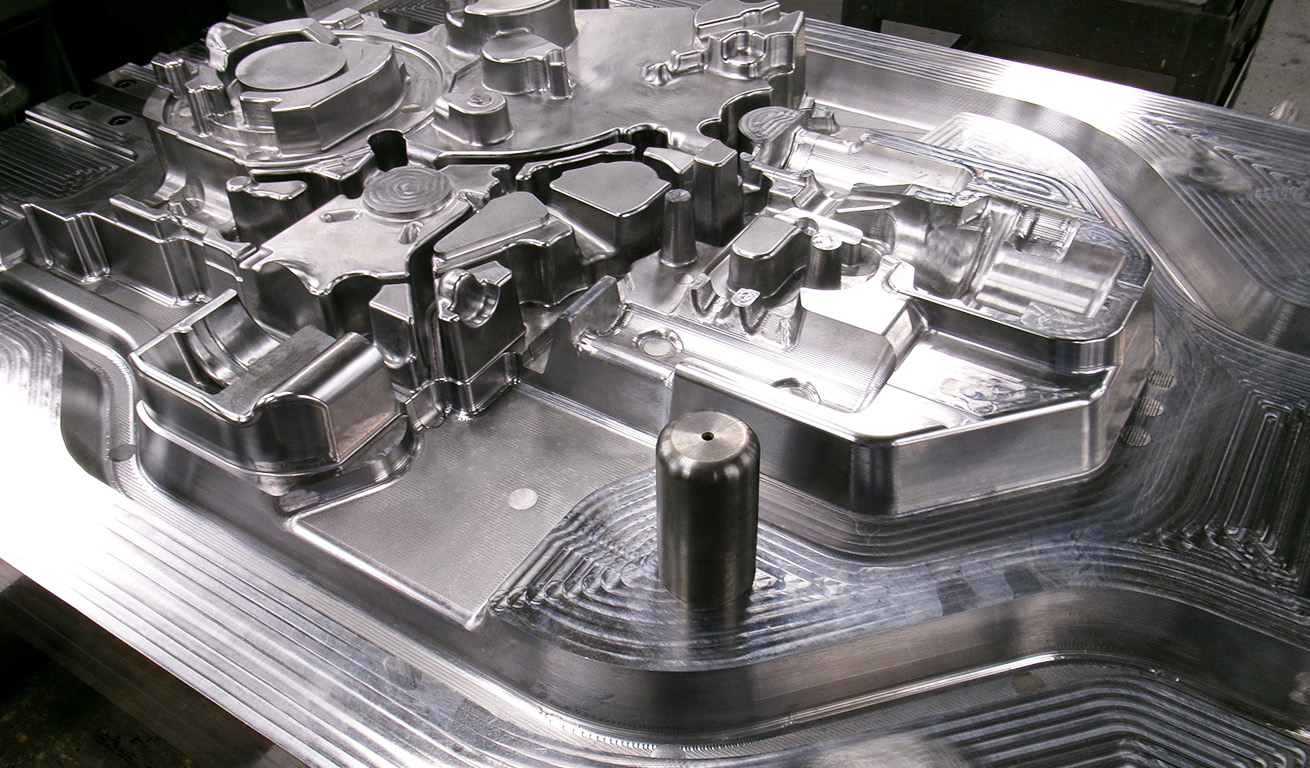

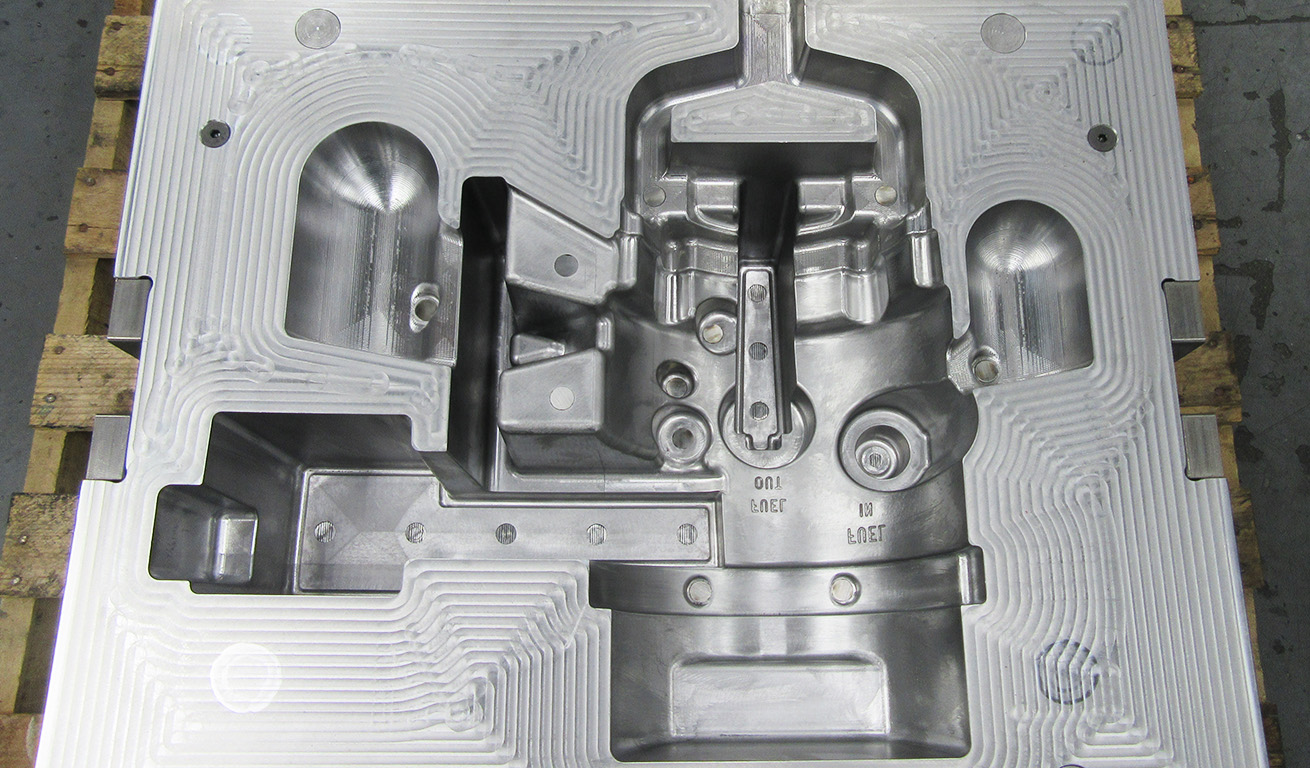

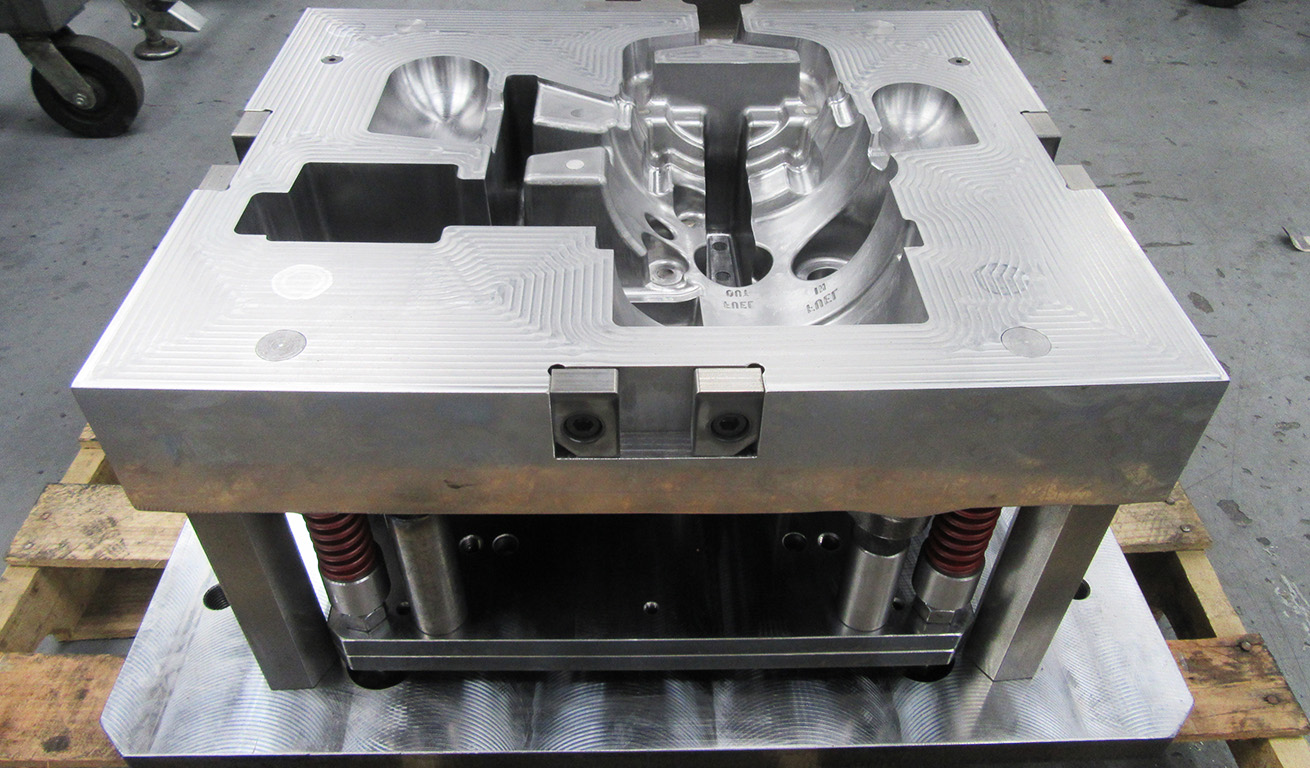

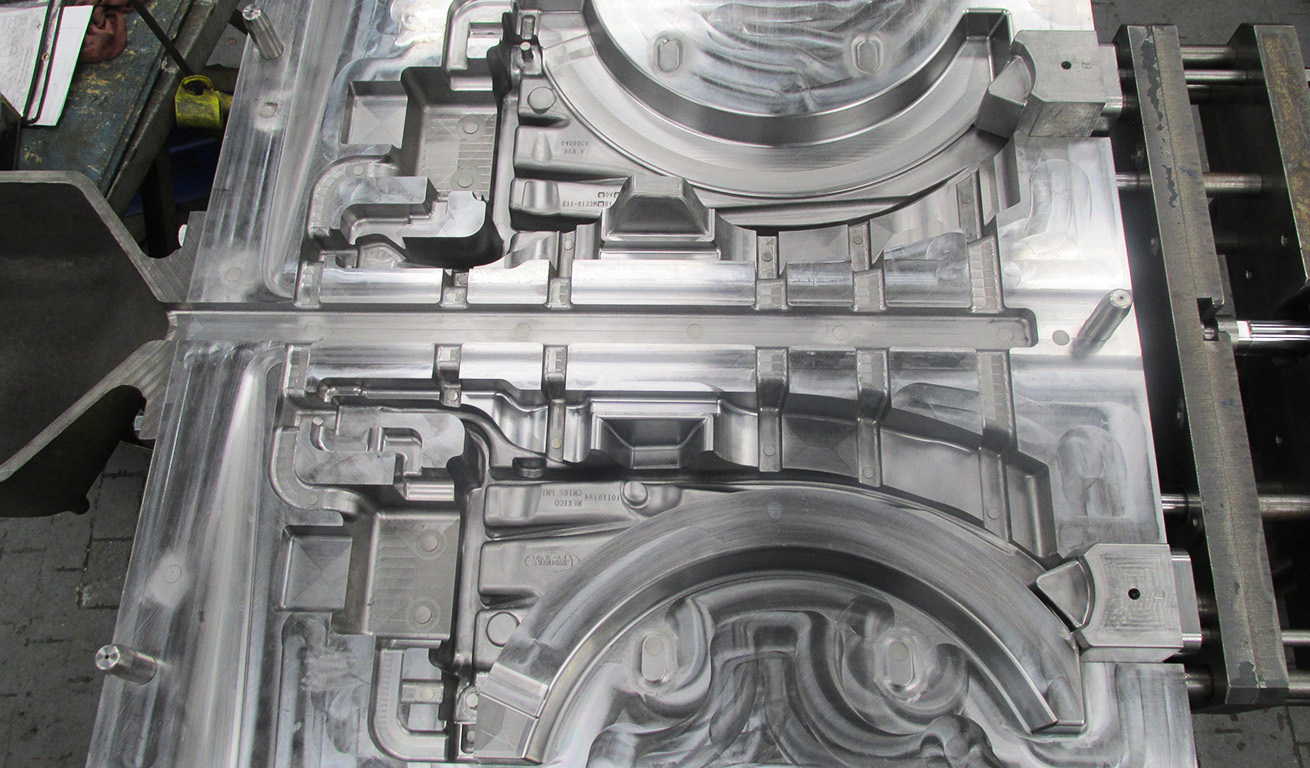

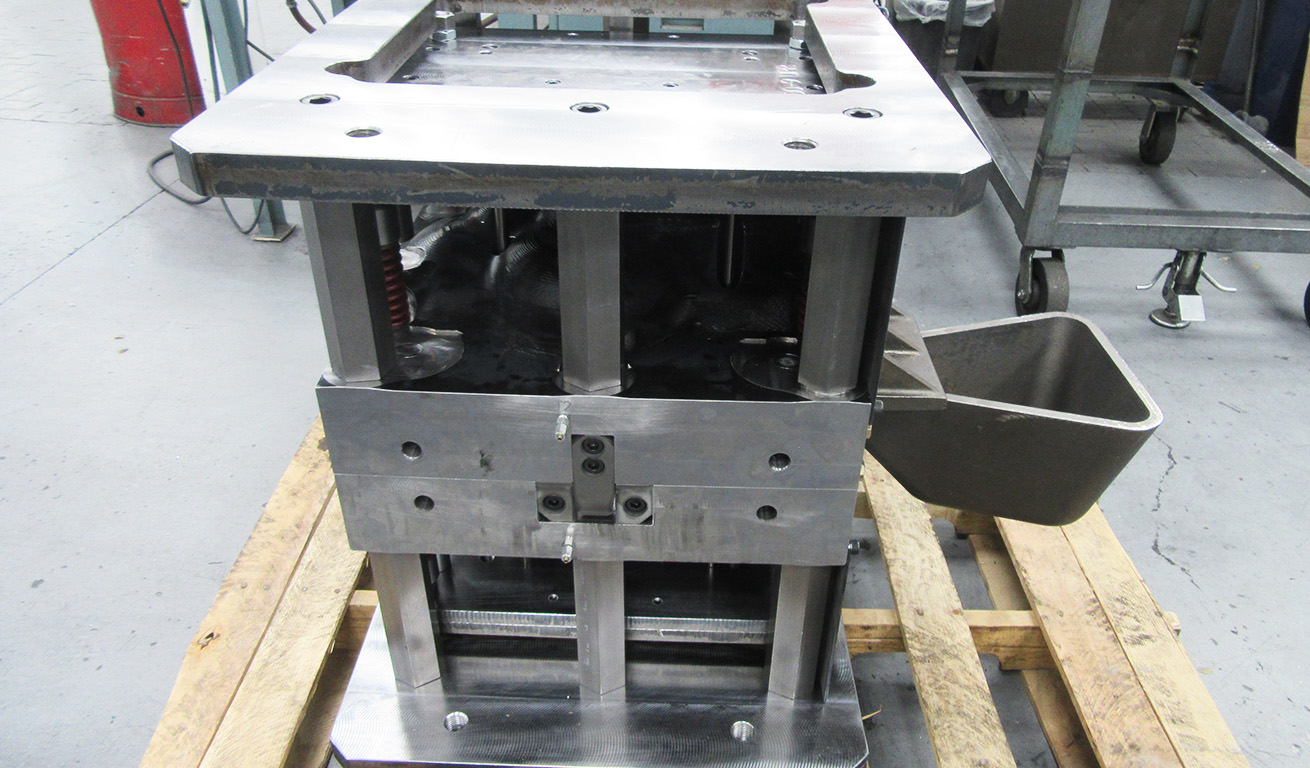

Effective semi-permanent molds accommodate undercuts necessary for interfacing with cores properly and accurately. When engineered correctly, foundry personnel can avoid constantly tinkering with molds and cores to get parts cast properly.

We’ve created semi-permanent molds to handle simple external undercuts, complex undercuts with multiple cavities, and core package interfacing.

Engineered with your foundry in mind

Gas venting solutions that range from simple to complex

Because semi-permanent molds have cores, gas builds up, requiring exhaust. Our design engineers account for this with a variety of venting methods. Parting vents, sintered vents, insert venting, long channels, vacuums — you name it, we’ve done it.

Semi-permanent mold technical specifications

Semi-permanent molds from Anderson Global are durable, reliable, and designed to interface correctly with their cores at temperature.

- Steel (P20, 4140, H13) and iron molds available

- While aluminum (356-T6, 355-T6, 319-F, 357-T6) is the most common casting material, we also work with others

- We’ve designed for many machines, including CMH Hall’s, Stahl’s & Eckle’s. No matter your molding machine specifications, we can design a solution for you

- Sand core options include shell cores, air set cores, and gassed cores

The total solution for your foundry mold needs

Whether your needs are complex, simple, or somewhere in between, our expertise ensures you get durable, reliable equipment that creates accurate and consistent parts from the first pour.

-

A one-stop shop for your whole project

Design, simulation, casting process, machining, benching, validation — we’ll meet you anywhere in your process. No matter the challenge, we can solve it in our Michigan facility.

-

Decades of experience

Our team of design engineers and journeyman patternmakers have delivered hundreds of molds and core boxes across every industry. And their expertise is on call when you need it.

-

Modern, data-driven designs

All of our molds and core boxes start in the digital world. Problem-solving in simulations keeps issues out of your foundry and generates accurate data that makes machining, maintenance, and repairs easy.