Workholding Fixtures

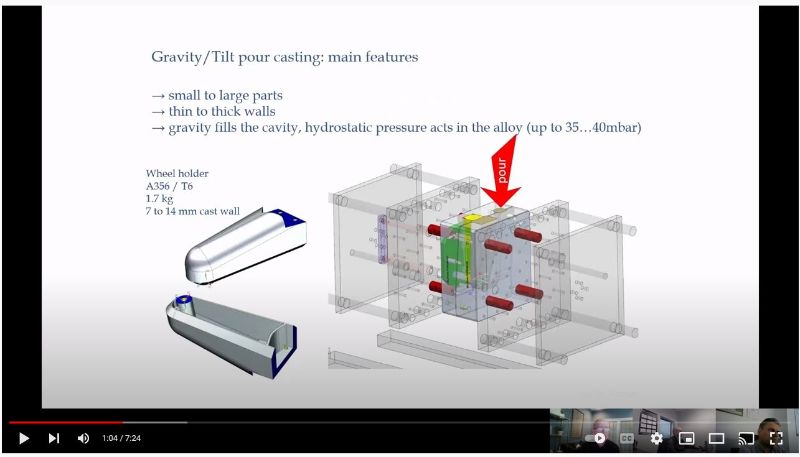

What makes a quality workholding fixture? Collars. Holes. Mounting capabilities. Ultra-tight tolerances. Some component features just aren’t possible to achieve by simply pouring metal. In fact, a lot of castings need additional machining to ensure the parts function as they should. And if you have a part that needs additional machining, you need a workholding […]