When you’ve got to get it right the first time, sometimes it’s all right to put all your eggs in one basket — especially when it comes to tooling design and supply.

For one American foundry, the decision to partner with a turnkey tooling provider with comprehensive in-house engineering, advanced simulations, and expert patternmakers streamlined their tooling procurement and bolstered their reputation with one of their biggest customers.

Working with multiple parties results in unreliable tooling development

Eagle Aluminum Permanent Mold Castings, located in Muskegon, MI, primarily manufactures components for the automotive, oil & gas, agriculture, and heavy trucking industries.

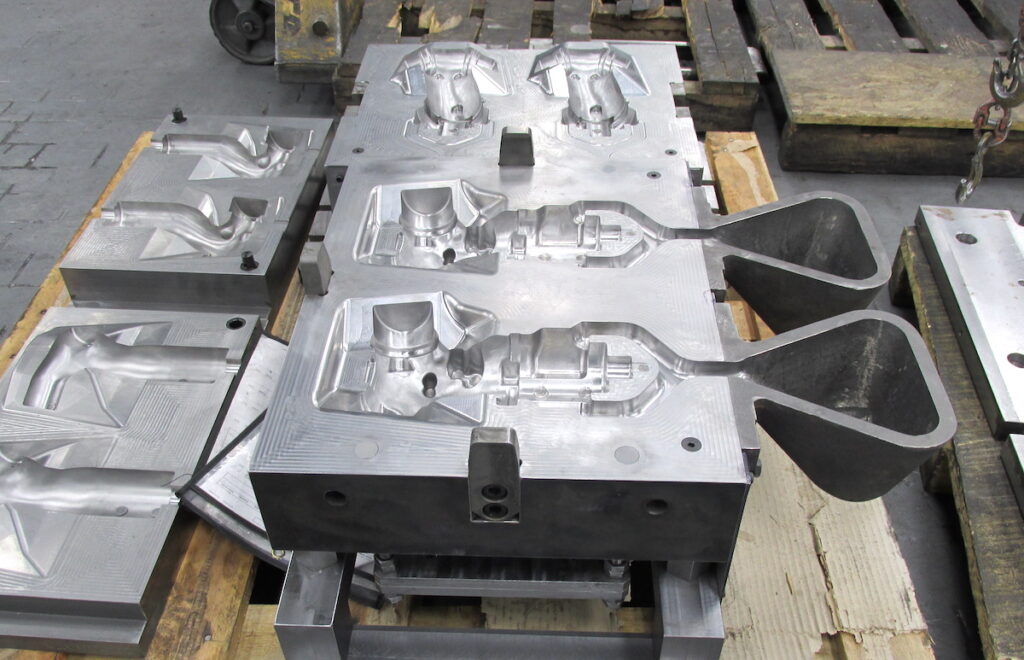

One of their crucial customers, a leading American motorcycle manufacturer, needed to source a complex set of intake manifolds that required multiple core boxes and permanent mold tooling systems.

The customer asked Eagle Aluminum to help make the part’s design more friendly to the permanent mold process.

Among their many challenges, Eagle Aluminum had to decide how to move parting lines and suggest additional draft angles at precise locations. They also wanted to remove the need for additional slides or cores to develop the best tooling at the lowest possible price.

But to do this, Eagle President Mike DeVoursney had to coordinate four different parties — the customer, the design team, a third-party mold flow analysis provider, and the tooling supplier.

Eagle Aluminum would design gating schemes in house and send them to a third party for mold flow analysis and solidification simulations. Then, Eagle would take the data, make the appropriate alterations, and send designs back for customer approval. Finally, they would send specifications to a tooling supplier.

This cumbersome process increased lead times as Mike waited for and relayed responses among the stakeholders. And if his tooling supplier wouldn’t pick up the phone, there wasn’t much he could do about it.

It got so bad Mike once had to leave his family on Christmas Eve to deal with a tooling delay.

“I had to leave Christmas Eve dinner with my family, extended family, mom, grandparents, everything, to come here and receive a late tooling delivery, because the customer had to have parts the second week of January,” Mike said.

He swore that was the last time he’d let that happen. He needed a single point of contact to provide reliable simulations, enhanced tooling designs, and faster results. And that’s what he got by working with Anderson Global — the design, engineering, and simulation capabilities to make it happen.

“That’s why having a supplier like Andersen Global you can put your faith in and know that they’ll deliver on what they say, the value on that is huge,” Mike said.

He worked with Anderson Global on a prior complex tooling project and knew they were a reliable source that provides accurate information and feedback from start to finish. Their turnkey tooling solutions greatly reduce the risk of miscommunications, delays, and costly errors.

“Working with a single contact and supplier shortens the responsiveness between myself and my customer, allowing me to focus on production and other items that are needed while still being able to manage the design and process of the tool itself,” Mike said.

The Anderson Global advantage: Advanced simulations, optimal designs, and better castings

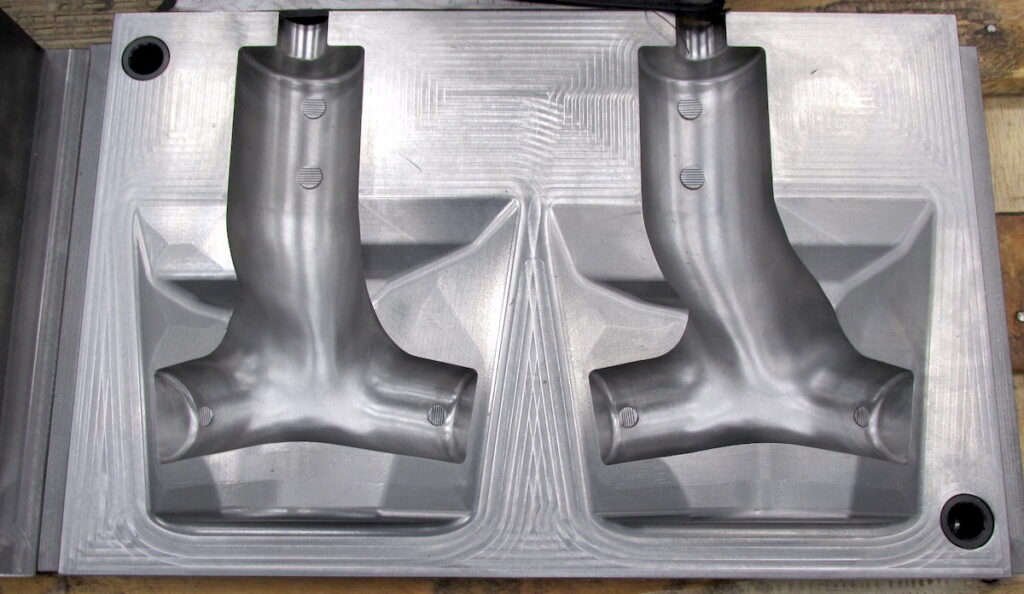

Eagle Aluminum already produced an intake manifold casting for this motorcycle manufacturer. Anderson Global designed a new gating scheme that incorporated much of the prior tooling and worked within Eagle Aluminum’s current process.

“With Anderson, their engineering capabilities impressed me the most,” Mike said. “From start to finish, it’s really a turnkey solution. We can provide all the pertinent information, and they can provide suggestions on the design, run the simulations, and provide feedback all through one source.”

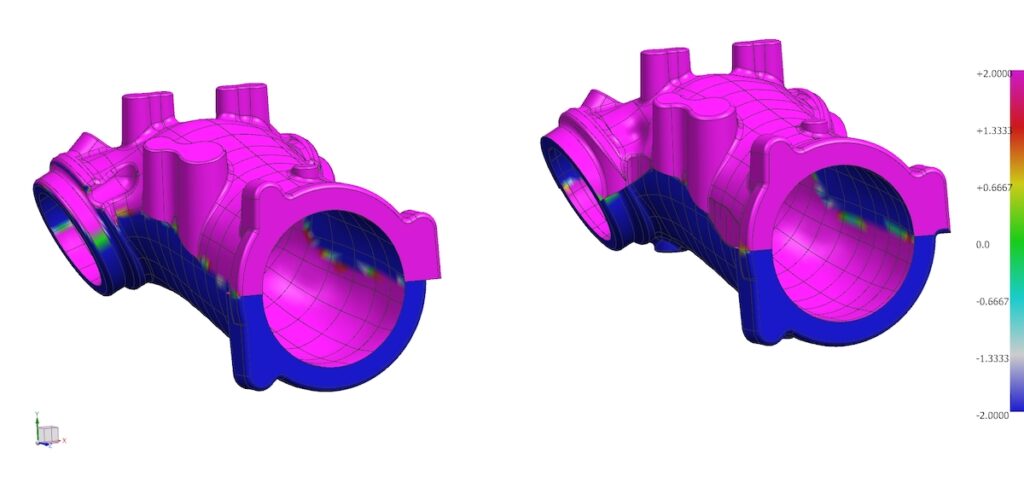

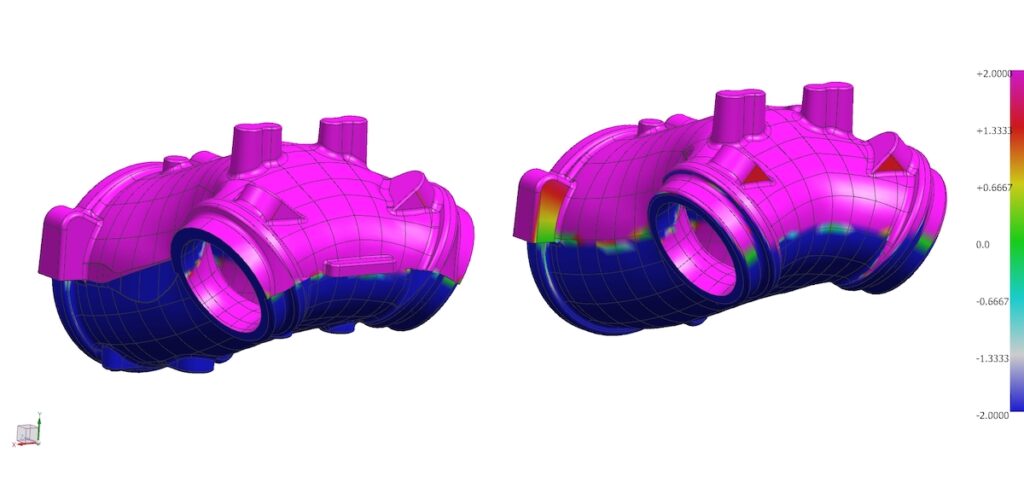

They also provided expert mold flow analysis and solidification simulations to prove the tooling would produce quality castings.

Eagle Aluminum provided Anderson Global with their CAD files and operating parameters. Anderson’s engineers took the design and ran a highly detailed mold flow analysis. This allowed them to identify potential porosity, trapped gas, and turbulence that otherwise would’ve been concealed within the mold.

The advanced insights offered everything they needed to perfectly position parting lines, determine proper draft angles and redesign the gating system to create stronger castings.

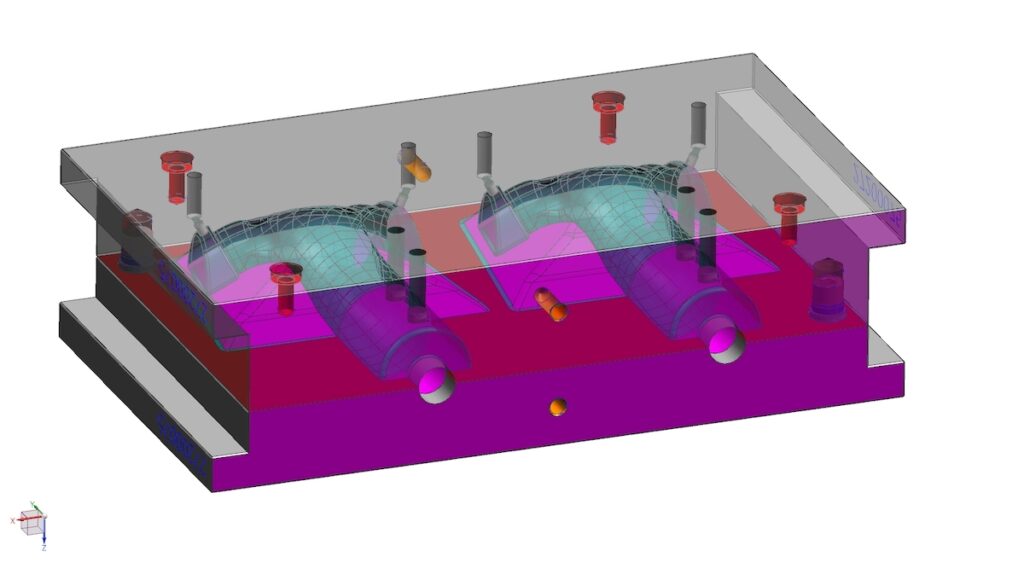

And since Anderson Global already knew Eagle Aluminum’s casting process, they incorporated the tool seamlessly into their system and provided a full view of what the tool would look like in production.

“The engineering is probably the most valuable, but the thing I was most impressed with was how they were able to take it from a CAD file to designing the tool, and then producing that tool in the actual molds that we run here,” Mike said. “They showed how it would line up, how it would bolt up, the actual footage of the tool in the press, and exactly how it would look when it gets to our facility.”

On top of all that, Mike enjoyed working with their friendly and reliable team. He even has four of their cell phone numbers on speed dial.

“They’re excellent people,” Mike said. “They’re very responsive. You’re able to call them up even on their cell phone and get a response. If they don’t have an answer for you right then, they can get to you the same day. They’re very cordial, respectful people to work with and very reliable and responsive for everything.”

Comprehensive tool engineering creates tighter timelines, lower bids, and satisfied customers

Mike had every reason to work with Anderson Global. In addition to the simplicity of having one point of contact, Anderson also provided the lowest bid by more than 5% and the lowest lead time by two weeks.

This allowed him to be more responsive to his customer, follow their strict timeline and provide high-quality sample parts that they could use for pre-production planning.

And he was able to do it all a week ahead of schedule.

“Not only were we able to provide the parts ahead of schedule, the design of the tool and the gating scheme and multiple simulations all were accurate, and we were able to provide a sample part that passed feedback on our first try,” Mike said.

Working with a reliable turnkey tooling provider saved Eagle Aluminum the added expense of tooling delays and reworks. These challenges are all too common with less capable tooling providers. The loss of future business — and respect — from customers as a result can put a business in a tailspin.

Eagle Aluminum doesn’t put their reputation on the line. Instead, they go to one supplier with reliable tooling engineers, technicians and patternmakers to get the job done right from day one. And that pays off every time.

“With every project I work with Anderson, I’m very satisfied with their ability to make start-to-finish design suggestions, provide multiple analyses, and provide a tool within the designated timeline,” Mike said. “The castings that we produced were very representative of the mold flow analysis and the actual cycle time we put on the parameter itself. They’re an excellent tooling supplier that can be relied on both for the information they provide and for the timeline they’re able to keep.”

If you want to be like Mike and streamline your tooling design, procurement and delivery, reach out to the tooling experts at Anderson Global. Let’s get started on your next complex tooling project and finish with tighter timelines, better castings and more satisfied customers.