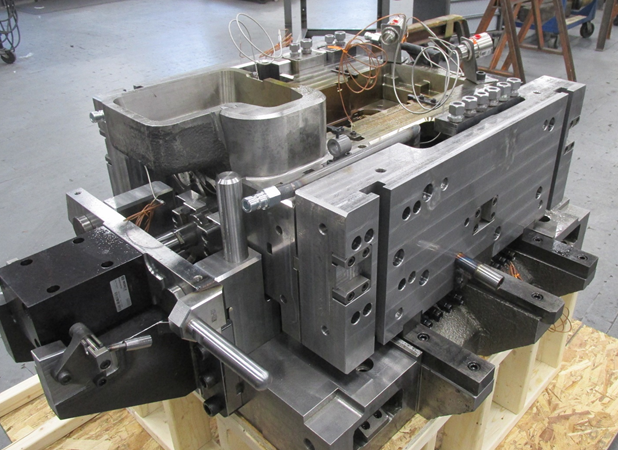

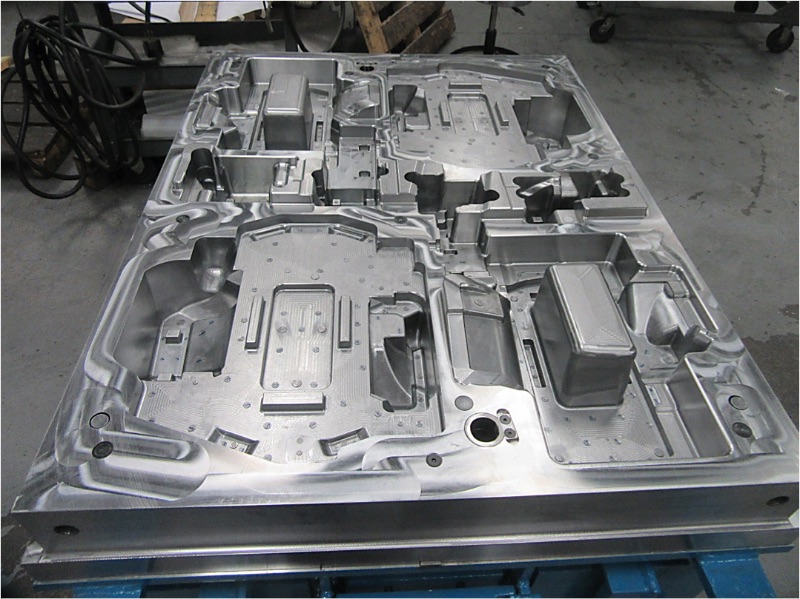

Precision metal casting molds for high-quality parts

Cheap molds cost more than they’re worth in downtime, faulty parts, and upset customers. For accurate castings, choose a premium metal casting mold engineered and manufactured by Anderson Global.

Permanent and semi-permanent gravity and tilt molds, low-pressure and counter-pressure tooling, core box tooling, sand tooling and more

CAD/CAM systems, 3D solid modeling, solidification and core blowing simulations and more

Expert journeymen patternmakers apply the final touches to fit assemble and test molds for precision casting

Reduce time and expense on mold design

State-of-the-art design software and manufacturing capabilities allow you to cast high-quality parts from the first pour. With Anderson, you can:

- Enhance designs and processes with fully featured 3D models, CAD/CAM, and process simulations

- Access the tooling expertise you need to accelerate production and increase profits

- Get the perfect tooling solutions the first time and avoid costly downtime caused by multiple reworks

Consistent lead times, no surprises

Don’t wait on delays and mistakes when we can deliver molds faster, better. We offer quick turnarounds, even for tight tolerances, complex geometries and high-performance products. Business is less stressful when you:

- Know your custom molds will meet customer requirements on time

- Trust a service partner to answer your call during emergency downtime

- Buy domestic and skip shipping delays

Maximize production capacity, get to market faster

Increase your casting capacity and quality with accelerated solutions like rapid prototype-to-production soft tooling and five-axis CNC high-speed machining centers. You can expedite:

- Casting production for low- and high-volume parts

- Product development, design, testing, and evaluation

Foundry Case Study

“Not only were we able to provide the parts ahead of schedule, the design of the tool and the gating scheme and multiple simulations all were accurate, and we were able to provide a sample part that passed feedback on our first try.”

Mike DeVoursney, President, Eagle Aluminum Cast Products